摘 要:傳統的油基鉆井液采用有機土作為增黏劑來增加懸浮重晶石的能力,是一種含土相的油基鉆井液,高密度條件下含土相油基鉆井液流變性控制困難限制了其應用的范圍。為此,以新研制的復合型乳化劑(G326-HEM)為核心,構建了無土相油基鉆井液體系,并對該配方進行了優選和性能實驗。結果表明:①無土相油基鉆井液體系無須使用輔乳化劑、潤濕劑,具有配方簡單,高密度條件下流變性好等特性;②與含土相鉆井液相比,高密度條件下塑性黏度、終切力低,降低了高密度鉆井液因黏切高誘發井漏的風險,可節省l0%的基礎油;③塑性黏度和動切力隨著油水比的降低而升高,不同密度下的油基鉆井液選用不同的油水比;④無土相油基體系配方對基礎油的適應性較廣,可廣泛應用于合成基、礦物油基鉆井液。結論認為,該成果較好地解決了無土相體系在高密度條件下的電穩定性弱、懸浮穩定性差的難題,為頁巖氣及其他非常規氣藏規模開發提供了技術保障。

關鍵詞:油基 鉆井液 頁巖氣 水平井 乳化劑 無土相 電穩定性 懸浮穩定性

Development of a clay-free oil-based drilling fluid with a low shearing force and high density

Abstract:A traditional clay oil-base drilling fluid is added with organic soil as a tackifier to increase its sufficient barites suspension properties.However,due to its high density,its rheological properties are difficult to control,which restricts its wide application.Therefore,a clay free oil-based drilling fluid system was established with the focus on a newly-developed composite emulsifier(G326-HEM),and the optimization and performance tests wer;performed on this formula.The test results indicated that:(1)neither auxiliary emulsifiers nor wetting agents were necessary,and this drilling fluid was featured by a simple formula and a good rheological property even with high density;(2)compared with a clay drilling fluid with high density,this clay free oil-based drilling fluid had a low plastic viscosity and a shearing force to reduce a potential circulation loss caused by high viscous shearing,which saved the base oil by l0%;(3)the plastic viscosity and dynamic shear force increased with the decrease of oil water ratios and different oil-water ratios were selected to prepare oil_ba驢drilling fluids with different densities;(4)the formula of the clay free oil base svstem was greatly adaptable to base oil and could be used for compounding based and mineral oil-base drilling fluid.This fluid can not only solve such problems as weak electrical stability and poor suspension stability of clay-free system under high density but provide technical support for the scale development of shale gas and other unconventional gas reservoirs.

Keywords:oil base drilling fluid,shale gas,horizontal well,emulsifier,clay free,electrical stability,suspension stability

目前我國在開發頁巖氣及非常規氣藏的過程中使用的油基鉆井液[1-4]是一種含土相油基鉆井液,采用有機土作為增黏劑、懸浮重晶石。在應用過程中暴露出高密度條件下含土相油基鉆井液流變性控制困難,當量循環密度高,在起下鉆或開泵時激動壓力較高,易誘發井漏或井壁失穩,亟需開發一種新型油基鉆井液解決上述難題。例如四川某區塊JH-11井與QL-6井在鉆遇高壓層位壓井時,由于含土相油基鉆井液體系流變性差,誘發漏失,JH-11井漏失油基鉆井液450m3,直接經濟損失630萬元,處理復雜損失工時28d。QD6井漏失油基鉆井液520m3,直接經濟損失728萬元,處理復雜損失工時35d,井漏的同時也伴隨嚴重的井控風險[2]。

使用油溶性或油溶脹性聚合物提高鉆井液的黏度和切力,代替有機土,以復合型乳化劑G326-HEM為核心構建了無土相油基鉆井液體系[5-7]。具有塑性黏度低、靜切力小、當量循環密度低等突出特點。無土相油基鉆井液只需要很小的驅動力,即可破壞其形成的空間結構,解決高密度含土相鉆井液因結構強度太大而造成憋泵、開泵泵壓過高、當量循環密度過大誘發井漏的問題[8-10]。

1 無土相油基鉆井液體系的構建

1.1 乳化劑的用量

在無土相油基鉆井液中,由于沒有有機土的作用,鉆井液體系的電穩定性差,加重材料極易沉淀,針對上述的特點,對乳化劑進行針對性研究,合成出復合型乳化劑(G326-HEM)。該乳化劑不需要與輔乳化劑復配使用,由于其自身具有對加重材料的潤濕功能因此配制高密度油基鉆井液也無須使用滑濕劑,以該乳化劑為核心構建無土相油基體系,與以往含土相油基鉆井液相比極大簡化了體系配方[11-13]。

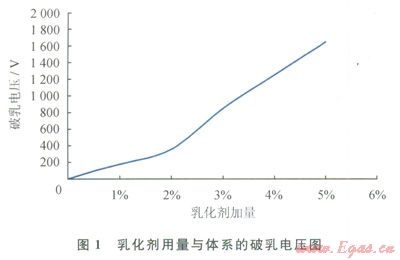

采用已有的實驗方法u陽得到復合型乳化劑G326-HEM加量與體系電穩定性能結果(圖1)。

當乳化劑加量大于3%時,體系的破乳電壓增加較快,加量為3%時,體系的破乳電壓達到850V,而當乳化劑加量5%時體系的破乳電壓已經達到1650V。考慮當乳化劑加量為3%時,體系的破乳電壓已經能夠滿足需要。因此選用乳化劑加量為3%。

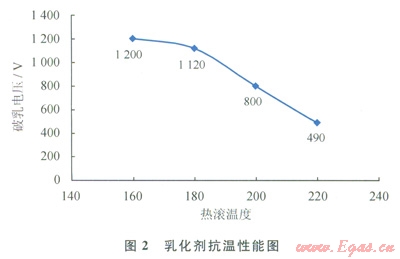

1.2 乳化劑的抗溫性能

測試了不同溫度熱滾前后體系的電穩定性,以此考察乳化劑的抗溫性能。由圖2可知,熱滾后的破乳電壓均高于400V,但200℃以上破乳電壓下降較快。因此將該乳化劑適宜的溫度定為200℃以內。

1.3 無土相油基鉆井液配方

通過配方試驗得到無士相油基鉆井液配方:基礎油+16%氯化鈣鹽水+3.0%復合型乳化劑(G326-HEM)+2.0%氫氧化鈣+4.0%降濾失劑G328+1.0%增黏劑+0.5%提切劑+加重材料。

2 無土相油基鉆井液體系的性能評價

2.1 不同油水比對體系性能的影響

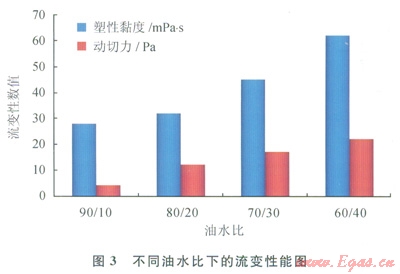

通過測試高密度不同油水比條件下鉆井液的流變性能,優選了高密度條件下無土相油基鉆井液的最佳油水比范圍(圖3)。

由圖3可知,油基鉆井液塑性黏度和動切力隨著油水比的降低而升高。當鉆井液密度為2.20g/cm3,適宜的油水比為80:20,此時鉆井液的塑性黏度和動切力均在合理的范圍之內,隨著鉆井液密度的繼續升高,鉆井液的油水比也升高,防止黏切過高。

2.2 無土相與含土相油基鉆井液對比

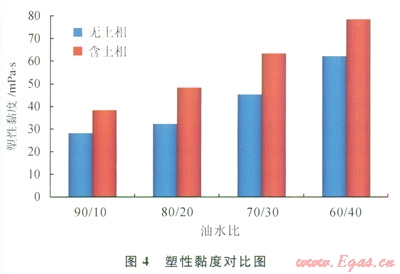

在相同密度條件下(2.30g/cm3),對這2種油基鉆井液的流變性能進行了實驗對比(圖4、5)。

由上述試驗結果可知,在相同密度、油水比條件下無土相油基鉆井液比含土相鉆井液的塑性黏度、終切力低,相同塑性黏度和終切力條件下,無土相油基鉆井液比含土相油基鉆井液的油水比低10%,無土相油基鉆井液可以節省10%基礎油,有利于調節流變性,降低了高密度含土相鉆井液因黏切高誘發井漏的風險。

2.3 不同基礎油對體系性能的影響

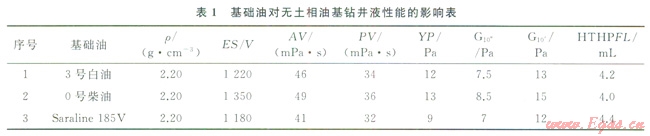

使用3號白油、0號柴油和氣質油Saraline 185V作為體系的基礎油,測試了不同基礎油配制的無土相油基鉆井液性能,試驗結果見表1所示。

由表l試驗結果可知,使用氣質油Saraline 185V配制的高密度無土相油基鉆井液塑性黏度、終切力最低,使用柴油配制的高密度無土相油基鉆井液高溫高壓濾失量和破乳電壓均最高。使用3種不同的基礎油配制的鉆井液各項性能均在合理范圍內,表明該配方對基礎油的適應性較廣,可廣泛應用于合成基、礦物油基鉆井液。

2013年10月,在四川省瀘州市通過了殼牌公司組織了鉆井液專家對無土相油基鉆井液體系性能的測試,與現場使用的油基鉆井液相比靜切力降低廠20.8%,達到了國外公司期望的高密度低切力的要求。

3 結論

1)以復合型乳化劑G326-HEM為核心構建無土相油基體系,無須使用輔乳化劑、潤濕劑具有配方簡單,高密度條件下流變性好等特性。

2)無土相油基鉆井液與含土相鉆井液相比,高密度條件下塑性黏度、終切力低,降低了高密度鉆井液因黏切高誘發井漏的風險,可節省l0%基礎油。

3)油基鉆井液塑性黏度和動切力隨著油水比的降低而升高,不同密度下的油基鉆井液選用不同的油水比。

4)無土相油基體系配方對基礎油的適應性較廣,可廣泛應用于合成基、礦物油基鉆井液。

參考文獻

[1]康毅力,楊斌,游利軍,等.油基鉆井完井液對頁巖儲層保護能力評價[J].天然氣工業,2013,33(12):99-104.

KANG Yili,YANG Bin,YOU Lijun,et al.Damage evaluation of oil-based drill in fluids to shale reservoirs[J].Natural Gas Industry,2013,33(12):99-104.

[2]王京光,張小平,卣輝,等.一種環保型合成基鉆井液在頁巖氣水平井中的應用[3].天然氣工業,2013,33(5):82-85.

WANG Jingguang.ZHANG Xiaoping,CAO Hui,et al.Application of an environmentally friendly synthetic base drilling fluid to horizontal drilling of shale gas wells[J].Natural Gas Industry,2013,33(5):82-85.

[3]徐同臺,彭芳芳,潘小鏞,等.氣制油的性質與氣制油鉆井液[J].鉆井液與完井液,2010,27(5):75-78.

XU Tongtai,PENG Fangfang,PAN Xiaoyong,et al.Performance of GTL and GTL based drilling fluid[J].Drilling Fluid&Completion Fluid,2010,27(5):75-78.

[4]岳前升,舒福昌,向興金,等.合成基鉆井液的研制及其應用[J].鉆井液與完井液,2004,21(5):1-4.

YUE Qiansheng,SHU Fuchang,XIANG Xingjin,et al.Research on synthetic drilling fluid and its application[J].Drilling Fluid&Completion Fluid,2004,21(5):1-4.

[5]李秀靈,沈麗,陳文俊.合成基鉆井液技術研究與應用進展[J].承德石油高等專科學校學報,2011,13(1):21-24.

LI Xiuling,SHEN Li,CHEN Wenjun.Technology study and development research of synthetic drilling fluid[J].Journal of Chengde Petroleum College,2011.13(1):21-24.

[6]蔣卓,舒福昌,向興金,等.全油合成基鉆井液的室內研究[J].鉆井液與完井液,2009,26(2):19-21.

JIANG Zhuo.SHU Fuchang,XIANG Xingjin,et al.An all-oil synthetic drilling fluid[J].Drilling Fluid&Completion Fluid,2009,26(2):19-21.

[7]張文波,戎克生,李建國,等.油基鉆井液研究及現場應用[J].石油天然氣學報:江漢石油學院學報,2010,32(3):304-305.

ZHANG Wenbo,RONG Kesheng,LI Jianguo,et al.Research and field application of oil base drilling[J].Journal of Oil and Gas Technology-Journal of Jianghan Petroleum Institute,2010,32(3):304-305.

[8]王京光,張小平,楊斌,等.一種抗高溫高密度飽和鹽水鉆井液的研制[J].天然氣工業,2012,32(8):79-81.

WANG Jingguang,ZHANG Xiaoping,YANG Bin,et al.Research and development of a saturated saltwater drilling fluid system with high density and high temperature resistance[J].Natural Gas Industry,2012,32(8):79-81.

[9]張艷,王濤,易飛.合成基鉆井液體系室內研究[J].精細與專用化學品,20ll,19(3):28-31.

ZHANG Yan,WANG Tao,YI Fei.Laboratory study oil synthetic base drilling fluid system[J].Fine and Specialty Chemicals,2011,19(3):28-31.

[10]羅健生,莫成孝,劉自明,等.氣制油合成基鉆井液研究與應用[J].鉆井液與完井液,2009,26(2):7-13.

LUO Jiansheng,MO Chengxiao,LIU Ziming,et al.The study and application of a GTL based drilling fluid[J].Drilling Fluid&Completion Fluid,2009,26(2):7-13.

[11]王中華.國內外油基鉆井液研究與應用進展[J].斷塊油氣田,2011,18(4):533-537.

WANG Zhonghua.Research and application progress of oil based drilling fluid at home and abroad[J].Fault-Block Oil&Gas Field,2011,18(4):533-537.

[12]張琰.合成基鉆井液發展綜述[J].鉆井液與完井液,1998,15(3):28-32.

ZHANG Yan.Review on the development of syntheticbased drilling fluids[J].Drilling Fluid&Completion Fluid,1998,l5(3):28-32.

[13]肖穩發,向興金,羅春芝,等.合成基鉆井液體系的室內研究[J].鉆采工藝,2000,23(3):80-83.

XIAO Wenfa,XIANG Xingiin,LUO Chunzhi,et al.Laboratory study on synthetic based muds[J].Drilling&Production Technology,2000,23(3):80-83.

[14]高海洋,黃進軍,崔茂榮,等.高溫下乳狀液穩定性的評價方法[J].西南石油學院學報,2001,23(4):57-59.

GAO Haiyang,HUANG Jinjun,CUI Maorong,et al.Method of evaluating stability of emulsions under highpressure and high temperature[J].Journal of Southwest Petroleum Institute.2001.23(4):57-59.

本文作者:張小平 王京光 楊斌 吳滿祥 王勇強

作者單位:低滲透油氣田勘探開發國家工程實驗室·中國石油川慶鉆探工程公司鉆采工程技術研究院

您可以選擇一種方式贊助本站

支付寶轉賬贊助

微信轉賬贊助